Ferrari has chosen Capital Markets Day 2025 as the occasion to reveal the production-ready chassis and components of its new electric car, the first full-electric model in the history of the Prancing Horse. This model is a milestone in the brand's multi-energy strategy, which encompasses internal combustion engines, HEV and PHEV powertrains, and now, fully electric drive.

The product of a radically new and innovative approach, the new Ferrari Elettrica combines state-of-the-art technology with superlative performance and the extraordinary driving pleasure that distinguishes every Ferrari model. Remaining true to the marque's engineering and artisanal traditions, each of the main components of this car has been developed and is manufactured in-house to ensure that the new Ferrari Elettrica also delivers the peerless levels of performance and uniqueness that only Ferrari can offer.

This car can be considered the culmination of a long journey of technological research into electrification that began with the first hybrid solutions derived from the 2009 Formula 1 car. From the 599 HY-KERS prototype of 2010 to the 2013 LaFerrari del 2013, and from the SF90 Stradale - the Maranello-based marque's first plug-in hybrid - and the 296 GTB to the 849 Testarossa presented recently, Ferrari has built and consolidated the know-how needed to develop an electric car capable of excelling in every dimension.

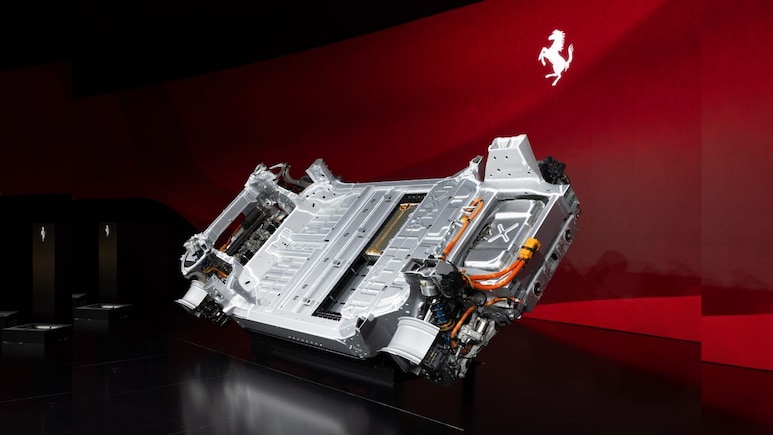

The strategy leading Ferrari towards the first electric model in its history was clear from the outset: that a model such as this would only be introduced once the technology available could ensure the superlative performance and authentic driving experience befitting the values of the brand. The project is now ready to go into production and boasts over 60 patented proprietary technological solutions. For the first time, both the chassis and bodyshell are manufactured with 75 percent recycled aluminum, contributing to an overall saving of 6.7 tons of CO2 for every vehicle built.

The architecture features short overhangs, an advanced driving position close to the front axle, and a battery integrated completely into the floorpan. The modules are installed between the front and rear axles, with 85 percent of them concentrated in the lowest position possible to lower the center of gravity and benefit driving dynamics. Notably, the Ferrari Elettrica gains a dynamic edge from a center of gravity 80 mm lower than an equivalent ICE model.

At the rear, Ferrari has introduced the first separate subframe in its history. It has been designed to reduce noise and vibration perceived in the cabin while still ensuring the stiffness and driving dynamics expected from a car from Maranello. The third generation of the 48 V active suspension system - originally introduced on the Purosangue and evolved for the F80 - takes ride comfort, body control, and vehicle dynamics to even greater heights by distributing cornering forces optimally over the four wheels.

The first all-electric Ferrari is equipped with two electric axles developed and built entirely in-house, each with a pair of synchronous permanent magnet engines and Halbach array rotors derived from F1 technology and industrialized for a series production application. The front axle has a power density of 3.23 kW/kg and an efficiency of 93 percent at peak power, while the rear axle attains a power density of 4.8 kW/kg and the same peak efficiency. Capable of delivering up to 300 kW, the front inverter is fully integrated into the axle and weighs just 9 kg.

Designed and assembled in Maranello, the battery has an energy density of almost 195 Wh/kg - the highest of any electric car - and features a cooling system designed to optimize heat distribution and performance.

Ferrari Elettrica - Technical Specifications

Performance

0-100 km/h 2.5 s

Top speed 310 km/h

Power >1000 cv in boost mode

Range >530 km

Dimension And Weight

Wheelbase 2960 mm

Weight circa 2300 kg

Weight distribution 47% front / 53% rear

Front E-Axle

Power at the axle 210 kW

Torque at the wheels 3500 Nm

Torque at the engine 140 Nm in Performance Launch mode

Power density 3.23 kW/kg (93% efficiency)

Engine revs 30,000

Maximum inverter power >300 kW

Weight 65 kg

Rear E-Axle

Power at the axle 620 kW

Torque at the wheels 8000 Nm

Torque at the engine 355 Nm in Performance Launch mode

Power density 4.80 kW/kg (93% efficiency)

Engine revs 25,500 giri/min

Maximum inverter power >600 kW

Weight 129 kg

Battery

No. Of cells 210 (15 modules with 14 cells)

Total power density 195 Wh/kg

Cell power density 305 Wh/kg

Gross capacity 122 kWh

Maximum voltage 880 V

Maximum recharge power 350 kW

Track Latest News Live on NDTV.com and get news updates from India and around the world